A successful production strategy is consistent with the company’s other functional strategies and benefits the overall corporate strategy.

It provides a strategic framework for management to orchestrate the global production network. In today’s dynamic business environment, it is crucial to understand the production strategy as continuous development reacting flexibly to changing conditions.

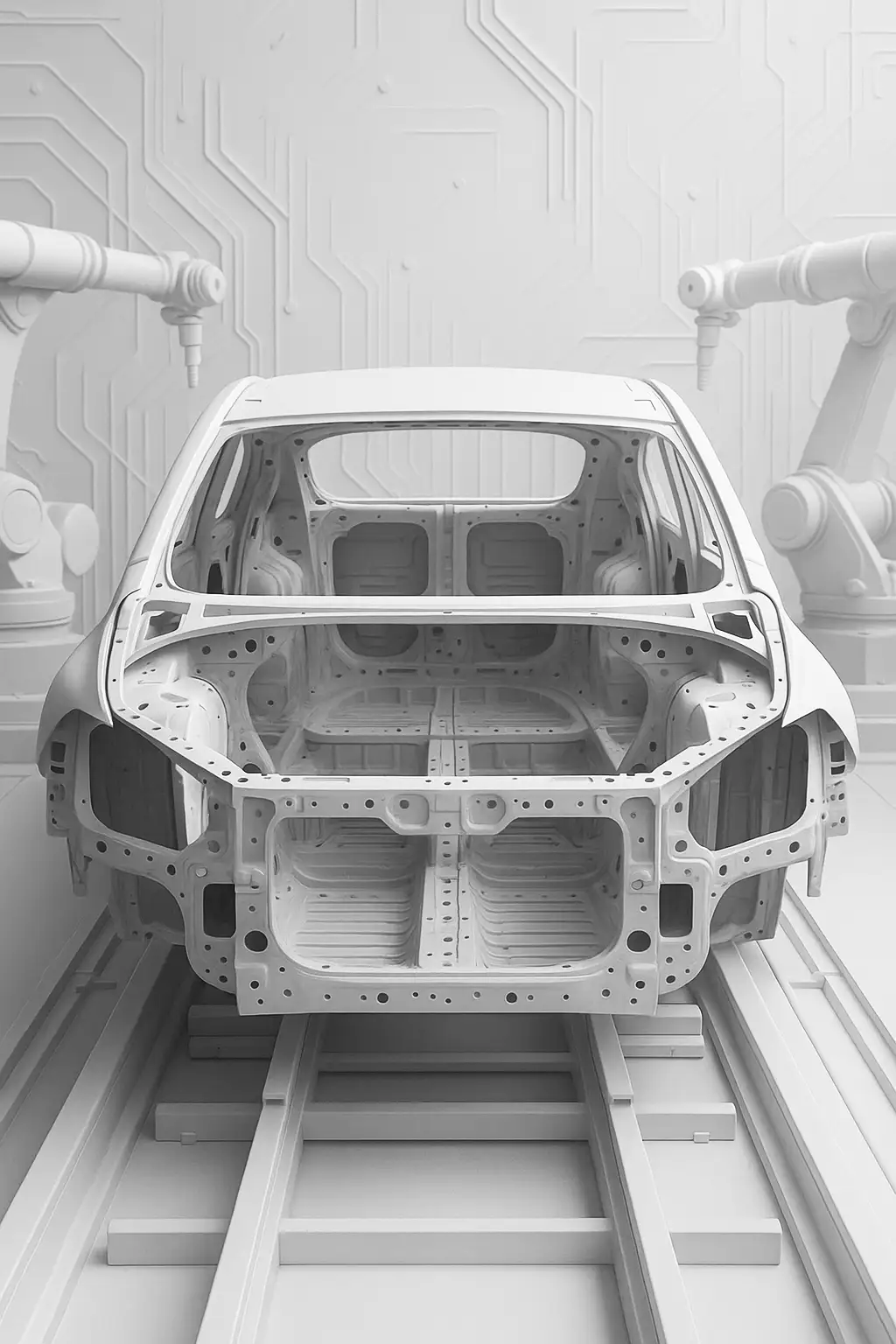

As production and digitization experts as well as interface, requirements and innovation managers, we are your ideal partner when it comes to taking a holistic view of production. Together with you, we anticipate potential as well as challenges and transfer them into strategic initiatives.

Tier-1 Supplier (Germany)

Automotive Startup (Germany)